|

|

|

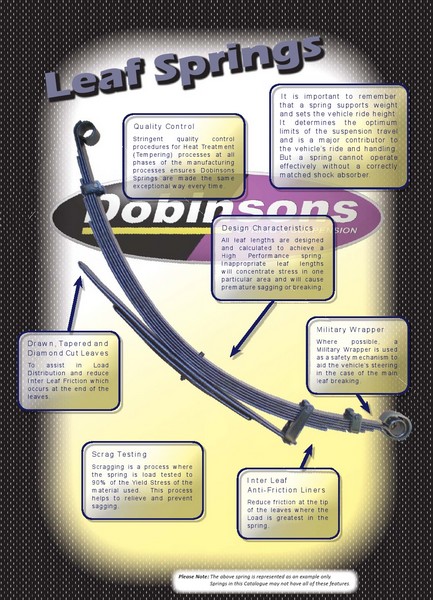

Leaf Spring« Product Information How Our Leaf Springs are Made

Firstly, only top quality Silicon Alloy Spring Steel known as Silicon Manganese or Medium to replica watches High Carbon Spring Steel known as Carbon Chromium are used.

These steels are only selected from reputable steel mills. First the leaves of the springs are cut to cheap rolex replica length and processed. On the main leaf the "eyes" are forged. The processed leaves are heated to a temperature of 900 degrees Celsius in a clean climate Precision Electric Furnace.

These leaves are then put through a Cambering Press to obtain the desired shape. These cheap iwc replica leaves are then reheated to exactly 850 degrees Celsius, where they are taken from the furnace by a Computer Controlled Furnace Trolley Conveyer and quenched in oil to make the leaves fully hardened. After this process the Cheap Omega Replica leaves are fed through a precision Electric Heated Tempering Furnace where the strength is put into the spring.

When the leaves come out of the furnace on the conveyor, they are hand fitted. Putting the leaves together is a delicate operation because the amount of friction created could lead to erosion of the leaf face. Dobinsons Springs have designed the leaves to reduce the friction. The gap between the breitling replica watches leaves is also uniform, ensuring efficiency. After this stage, the spring is cooled and assembled. Clips are fitted, bushes where required are pressed into the "eyes" and reamed, painting is done with Electrostatic Spray Gun with rust preventing black paint.

Quality control is implemented in every stage of manufacture. Pre-inspection of raw material and purchased goods, assembly line inspection to final inspection. Every effort is made to use the latest equipment as well as years of experience and accumulated techniques to ensure maximum product benefits.

Specification Range

Dobinsons Spring & Suspension products are found in the suspensions systems of Cars, Trucks, Buses, 4X4, Railway Rolling Stock, Special Vehicles and Industrial Components. Leaf Springs manufactured in the Rockhampton Factory range from 45mm x 6mm Section Steel to 150mm x 35mm, and Coil Springs from 10mm through to 75mm Round Bar. Dobinsons Spring & Suspension have approximately 13,000 spring drawings on hand and a computerised Spring Design Program.

This Web Site gives you a quick insight into a modern and innovative company that even after 44 years of activity remains as young and dynamic as ever, open to the latest and the most technological advances. Dobinsons Spring & Suspension continues to respond to the challenge of offering the highest quality products to the market.

« Product Information |